Is Land a Current Asset? A Guide for Owners & Bookkeepers

Quick Answer In virtually all standard bookkeeping and accounting frameworks, land is classified as a non-current asset, specifically as a fixed asset or property, plant,

Servicing a gas station isn’t just about fueling vehicles—it’s about protecting people, property, and the environment.

For professionals in the petroleum equipment service industry, staying compliant with environmental regulations isn’t optional. Failure to do so can result in catastrophic consequences like soil and groundwater contamination from underground storage tank (UST) leaks, fires, or air pollution from vapor emissions.

The cost of remediation is steep, and station owners are often financially and legally liable for cleanup, fines, and regulatory penalties.

As the frontline defenders of compliance, petroleum equipment service providers must know and enforce industry best practices and environmental standards. This article outlines key responsibilities and regulatory touchpoints to keep in mind.

Neglecting environmental standards can trigger a domino effect:

Routine testing of soil and groundwater ensures no fuel leaks have occurred. Federal UST regulations (40 CFR Part 280) require these checks to catch contamination early.

Secondary containment systems such as spill buckets help prevent releases during fuel delivery. These must be periodically tested for integrity.

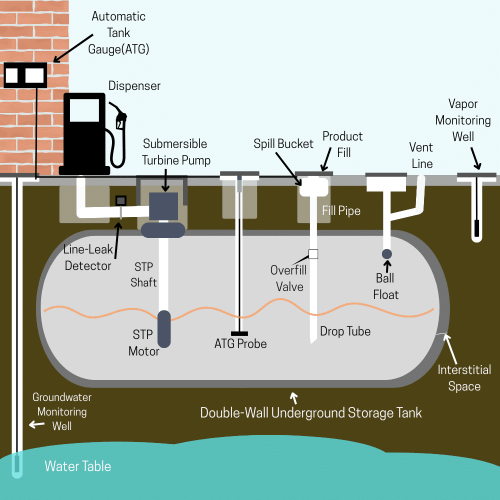

Automatic tank gauging (ATG) systems are one way to monitor fuel volume levels and detect leaks. They can meet federal tank testing requirements with either a static or statistical test. EPA rules mandate leak detection for all USTs holding petroleum. Regulatory requirements and release detection methods will vary for pressurized piping versus suction piping.

Pro Tip #1: Do not ignore the ATG alarm! Some operators get annoyed and turn off the ATG to get rid of the beeping. Respond immediately to an alarm or blinking lights.

USTs and piping must be protected from corrosion, often through cathodic protection systems, which need regular testing per EPA guidelines. Other methods include using a noncorrodible material for tanks or piping, electrical isolation, and secondary containment.

Monitoring pressure in tanks and piping systems ensures system integrity. Sudden drops may signal a leak. Automatic line leak detectors (LLDs) monitor line pressure and the flow restrictor or shutoff will slow or prevent product flow during a leak.

Pro Tip # 2: Use remote telemetry for 24/7 pressure monitoring.

Sensors used in ATGs and sump monitors must be routinely tested and calibrated to ensure they function correctly.

These sumps must be checked regularly for damage, liquid or debris, or leaks in the interstitial area. Visual inspections are typically required annually or more frequently depending on state requirements to maintain UST systems, but they don’t meet the EPA’s periodic integrity test requirements.

When a delivery hose disconnects from the fill pipe, spills can occur. Placing containment such as a spill bucket around the fill pipe catches these. Spill buckets, also known as a catchment basin, must be tested for liquid tightness. They need to be able to hold several gallons. This liquid needs to be removed with a pump or drain.

Overfill protection devices must activate at 90-95% tank capacity to restrict the flow and alert the transfer operator. This helps to prevent release when the tank gets close to being full. Types include automatic shutoff devices, overfill alarms, and flow restrictors.

Vapor recovery systems capture gasoline vapors during vehicle refueling or delivery. They can reduce air pollution and save money by preventing the loss of gasoline into the air.

These systems are regulated by federal and state agencies, such as CARB. Regulations vary by state, but key components include:

Accurate, up-to-date documentation is a cornerstone of compliance and protects you during audits.

Businesses must retain:

Your role in the petroleum equipment industry goes far beyond installation and service—you are the first line of defense against environmental disasters.

By staying informed and compliant, you protect not only your business but also public health and the environment.

Environmental safety is your legacy—don’t let shortcuts write your story.

This varies by jurisdiction, but most states require at least annual testing and maintenance.

Yes. Every tank fill port must be equipped with a spill bucket, and they must pass integrity tests every three years.

It’s a corrosion control method using electrical currents to prevent rust in UST systems. Without it, steel tanks are prone to failure.

Immediately notify the local fire department, state environmental agency, and the National Response Center (1-800-424-8802).

Subscribe to our newsletter

By submitting this form, I agree to receive marketing communication via phone call, email, or SMS from Aptora.

By submitting this form, I agree to receive marketing communication via phone call, email, or SMS from Aptora.